The first thing I learned was that it gives me a really big, fat sound, especially in the low register. The adjustments described below will illustrate just how much I like it:

1. For me, the tuba played flat. It may be fine for other tubists, but I had to hack half an inch off the main tuning slide. That was easy to do.

2. For me, the mouthpiece receiver is about an inch too high. (I am 5'10" tall.) I was able to play it by sitting on a stack of magazines. Then I found my wife's "kneeling pad" among her garden supplies. It weighs almost nothing and works well:

3. The tiny screws that hold the plastic stop arms on the aluminum rotors tended to loosen and pop out while I was playing. The finger paddle would then flip around and send the screw flying. After losing one, I found that the

rest of them were loose. I started carrying a 3/32" allen wrench to tighten them every day, but was afraid that over-tightening might strip the threads

in the soft aluminum rotors. I then found some stainless-steel cap screws with the same thread, but longer. (It's the same 3 X 0.5 metric thread that is used for European plastic valve guides. You can find them online.) The Tiger screws are 5 mm long, so only about 4 mm goes into the rotor. The replacement screws are longer, about 7.5 mm. The existing threaded holes in the rotor are deep enough to accept about 6 mm with the stop arm on. It's pretty easy to

clamp the screw in a vise between two pieces of hardwood, file about 1.5 mm off the tip, and round it off just a bit. These screws take a 7/64" allen wrench, and don't need to be tightened so often.

4. My biggest mistake was trying a drop of loc-tight on one of the screws that tended to loosen. It leaked into the top bearing, and that rotor would not budge the next day until I managed to break it loose with the bottle opener on my pocket knife. DON'T DO THIS! (More about that in #6, below.)

5. I have always maintained that personal comfort is one of the most important criteria in selecting a tuba, and for me the Tiger still left much to be desired in that department:

I made an aluminum extension for the first finger paddle, with a slot to accomodate the rib on the under side of the plastic paddle, and attached it with a nut, bolt, and washer:

For a while I rested my thumb on the second-valve pull ring, since the thumb ring is much too high for me, but the ring eventually broke. A fixed thumb ring in the right location for me would obstruct pulling the second-valve slide, so I made a thumb ring that can be flipped out of the way:

5. The Tiger's mouthpiece receiver is horizontal. I prefer to blow a little downhill. On a brass tuba I would bend the leadpipe to a more comfortable position, but that does not seem to be possible on a plastic tuba. I tried a sousaphone bit, but that made the mouthpiece much higher and too far back.

Then I remembered that I had an extra shank for my Dough Elliot mouthpiece.

I sawed it off at a small angle, rotated one piece 180 degrees, and soldered it back together. (That's how much I like this tuba!) I also made a thin brass sleeve to fit over the shank, making it about 3/4" longer. It works, but the

sleeve is now stuck in the receiver. (Not a problem)

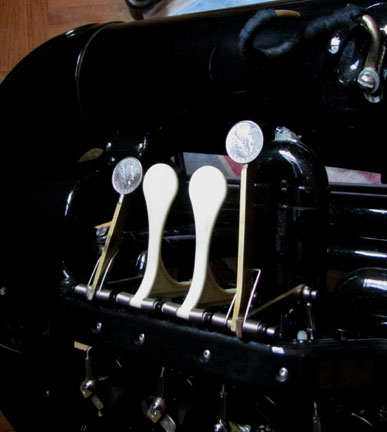

6. My Loc-tight experiment came back to bite me a few weeks later when that stop arm suddenly shattered while I was practicing. It was only then that I noticed that the plastic stop arms are hollow. As a temporary precaution I filled the others with J-B-Weld, a type of epoxy found in hardware stores. Then I made a crude metal replacement for the broken one. A more-skilled craftsman could make something better-looking, but mine works! It consists of three layers soldered together:

The three layers were soldered together while held in place by a stainless-steel nut and bolt. By trial and error I learned that I could keep them concentric and prevent solder from flowing into the holes by using aluminum spacers filed to fit snugly into the holes in the first and third layers.

7. I found that if the tuba is not played every day the rotors tend to get stuck. I tried putting a lot of valve oil into them before going away for a few days, but that did not help. They were stuck hard when I got back. I had to remove the stop arm and use pliers to turn the rotors to get them moving again. Then I discovered that the problem seems to be traces of saliva drying out in the valves. Now after playing I run some fresh water through the valves, back and forth a few times while wiggling them. Then I drain the water out, and the problem is solved. It also helps my piston tubas. Plain old water leaves no residue.

I have now replaced all four stop-arms with metal ones as described above.

I have used the Tiger in one band concert so far, and recently used it for "Pictures at and Exhibition" with an orchestra. (Bydlo was done on a euphonium, but the Tiger was great for the rest.) The tuba has drawn many compliments and inquiries; some wonder if it's carbon fiber. (Don't I wish!)

8. My extended first-valve finger paddle was the first to break. After unsuccessfully trying to repair it with JB-weld, I made replacement out of brass. Later, after the Tiger gig bag straps started failing, I began using a different gig bag with more padding. Since it was a top-loader, it broke off my fourth valve paddle. So I made another brass one to replace it:

a. The first layer was made from a brass strip 1/8" thick and 3/8" wide, with a 5 x 7-mm rectangular hole cut to fit snugly onto the top of the rotor shaft. (First I drilled a hole almost 5 mm in diameter, then I lengthened it with a chain-saw sharpening file, and finally shaped it with as small triangular file.) The brass stock can be found online.

b. The second layer (costing 25 cents) was cut from a coin. It has one hole drilled to fit the 3-mm screw, and a

second hole drilled and tapped with a 6-32 threaded. I cut matching threads onto a short brass rod to screw into that hole. (That rod hits the bumpers.)

c. The third layer was made from the same brass stock as the first. It has one hole big enough to accommodate the

cap screw head, and one smaller one that is tapped to accept the 3 X 0.5 mm screw that connects the linkage ball joint. The separation of those holes is 10 mm (to match the original) or 11 mm to make the finger stroke a bit longer and more piston-like, and to decrease stress on the rotor bearing.